SAE viscosity resources

-

SAE viscosity grades for engine oils

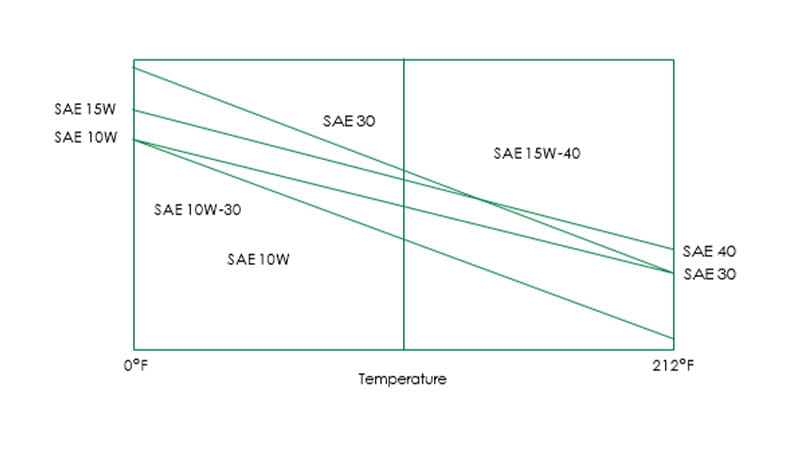

The Society of Automotive Engineers (SAE) viscosity grading system for engine oils consists of “W” grades that define low temperature viscosities and “straight” grades that put further limits on high temperature viscosities. The chart shown at the bottom of the page graphically represents the viscosity-temperature relationship of the SAE grading system with lines drawn to show the viscosity characteristics for several popular motor oils.

SAE viscosity grades for engine oils - SAE J300 DEC 99

SAE viscosity grade Cranking: cP @ °C max. (ASTM D 5293) Pumping: max cP with no yield stress @ °C (ASTM D 4648) Kinematic: cSt @ 100°C (ASTM D 445) High shear: cP @ 150°C & 106s-1 min. 0W 6,200 @ -35 60,000 @ -40 3.8 minimum - 5W 6,600 @ -30 60,000 @ -35 3.8 minimum - 10W 7,000 @ -25 60,000 @ -30 4.1 minimum - 15W 7,000 @ -20 60,000 @ -25 5.6 minimum - 20W 9,500 @ -15 60,000 @ -20 5.6 minimum - 25W 13,000 @ -10 60,000 @ -15 9.3 minimum - 20 - - 5.6 < 9.3 2.6 30 - - 9.3 < 12.5 2.9 40 - - 12.5 < 16.3 2.9 (for 0W-40, 5W-40 & 10W-40 grades)

3.7 (for all other grades)50 - - 16.3 < 21.9 3.7 -

Viscosity temperature chart

-

API service designation for gear lubricants

The automotive and petroleum industries in cooperation with the American Society of Testing and Materials (ASTM), Society of Automotive Engineers (SAE) and the American Petroleum Institute (API) have developed a service classification system to serve as a guide for recommending and marketing gear lubricants. Following is the API description:

API designation Description GL-1 Service of automotive spiral bevel and worm gear type axles, manual transmissions and spur gears operating under light load and mild conditions requiring no extreme pressure additives. GL-2 Same as GL-1 except under medium load of moderate conditions. Will contain mild extreme pressure additive for worm gear protection. GL-3 Same as GL-1 and GL-2 except operating under moderately severe conditions. GL-4 Service of automotive hypoid gears operating under both low speed, high load (trucks and tractors) and high speed, low load (passenger car) conditions. GL-5 Same as GL-4, but under more severe operating conditions, such as shock loading. -

SAE viscosity grade for gear lubricants

The Society of Automotive Engineers (SAE) has devised a method for classifying the viscosity characteristics of gear lubricants as well. Gear lubricant viscosity grades should not be confused with engine oil viscosity grades. A gear lubricant and an engine oil having the same viscosity will have widely different SAE viscosity grade designations as defined in the two viscosity classifications. For instance, an SAE 80W gear lubricant may have the same viscosity as an SAE 20W or SAE 30 engine oil and SAE 90 gear lubricant viscosity can be similar to that of an SAE 40 or SAE 50 engine oil. Following is a table with the SAE gear lubricant viscosity grades:

- Axle and manual transmission lubricant viscosity classification

- SAE J306 OCT 91 summary

SAE viscosity grade Maximum temp. (C) for viscosity of 150,000 cP Viscosity (cSt) @ 100° minimum 70W -55 4.1 minimum 75W -40 4.1 minimum 80W -26 7.0 minimum 85W -12 11.0 minimum 90 - 13.5 - <24.0 140 - 240 - <41.0 250 - 41.0 minimum -

AGMA and ISO viscosity grade classifications

The American Gear Manufacturers Association (AGMA) and the International Standards Organization (ISO) have established viscosity standards for hydraulic fluids and industrial gear lubricants. Following are the AGMA Lubricant Numbers, the corresponding ISO Grade and the viscosity ranges:

AGMA no. ISO viscosity grade Viscosity range cSt @ 40°C 1 46 41.4-50.6 2 & 2 EP 68 61.2-74.8 3 & 3 EP 100 90-110 4 & 4 EP 150 135-165 5 & 5 EP 220 198-242 6 & 6 EP 320 288-352 7 (compounded) & 7 EP 460 414-506 8 (compounded) & 8 EP 680 612-748 8A (compounded) 1000 900-1100